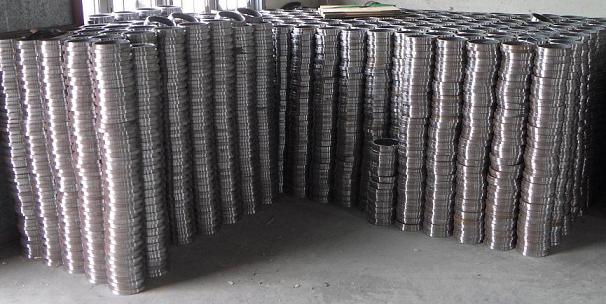

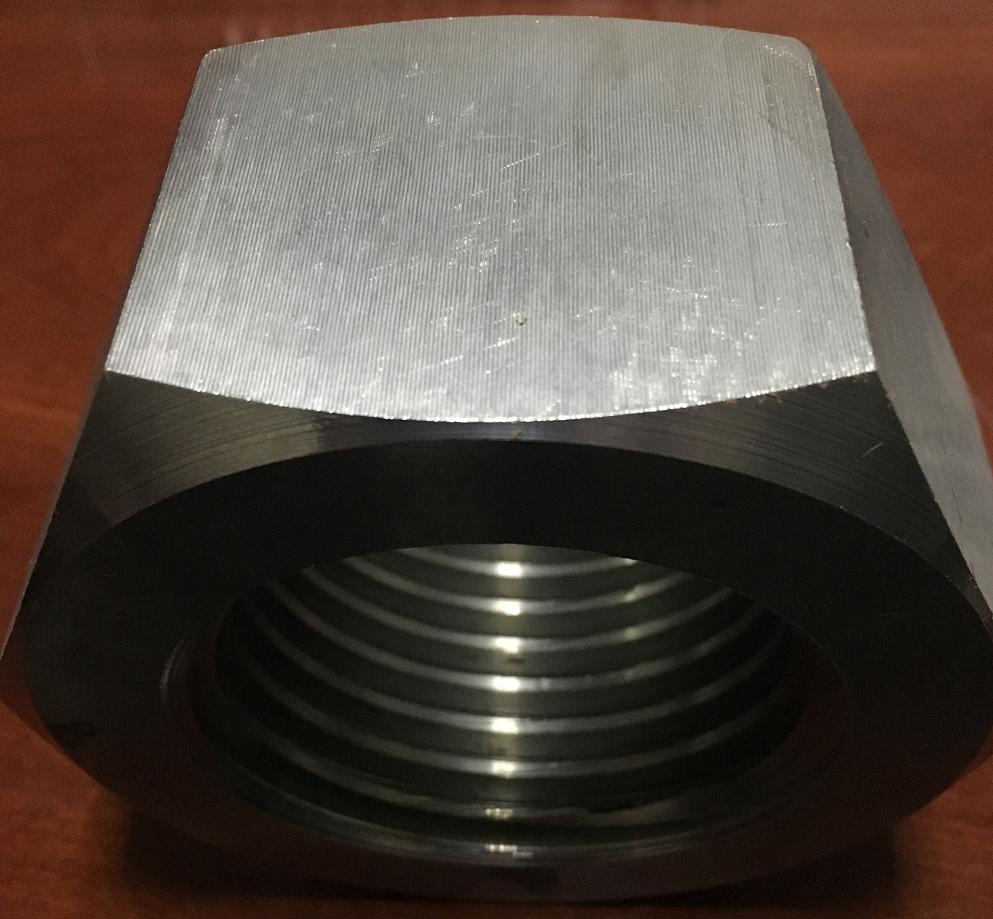

Drop Forging is a steel shaping process whereby a heated steel billet is placed on a lower die mould block, while an overhead, die-equipped ram hammer drives or “drops” down, forcing the metal to fill the contours of the two die blocks. Drop forging is used for mass production. drop forging process produces near net shapes that will require only a small amount of machining or finishing, thus reducing production costs.

Drop Forging is a steel shaping process whereby a heated steel billet is placed on a lower die mould block, while an overhead, die-equipped ram hammer drives or “drops” down, forcing the metal to fill the contours of the two die blocks. Drop forging is used for mass production. drop forging process produces near net shapes that will require only a small amount of machining or finishing, thus reducing production costs.

A wide variety of metals can be forged into high quality parts through the drop forging process. These materials include Carbon Steels, Alloy Steels, Stainless Steels, High Alloy Steels, Low Alloy Steels, Tool Steels, Aluminum, Titanium and much more.

Markets we serve:

- AUTOMOBILE: MAIN PRODUCTION FOR SAE 8620H FORGING PRODUCTS, AUTO FORGING, GEAR FORGING, STEERING KNUCKLE, CONNECTION ROD, PRECISION FORGED PARTS, 6061 ALUMINUM FORGING, 7075 ALUMINUM FORGINGS, BRASS FORGINGS, VALVE FORGING AND SO ON.

Wind Industrial Supplied Co.,has extensive experience in producing a wide variety of forged 3-D shapes — from the smallest to those weighing up to 25 lbs. We combine this experience with the ability to work quickly and flexibly to meet your forging needs.