The sand casting process is used typically for larger parts and for small quantities of parts. Sand casting is capable of making fairly complex shapes using relatively inexpensive wood patterns. Sand and containing a natural or synthetic binder, is packed around a wood pattern, the sand is then tamped down to provide the two-part mold with adequate strength. The pattern is then removed, leaving a negative form in the mold. Wooden models are used as material for the casting pattern at a relatively low cost. Due to relatively low tooling costs the casting method can be used for prototype manufacturing. The surface finish and casting tolerances are adequate for most purposes.

Wind Industrial Supplied Co.,Ltd (WIS) offers the Grey Iron castings, Gray Iron castings, the material grades include Germany standard GG 25 Grey Iron Castings, GG 25 Gray Iron Castings, EN-GJL-250 Grey Iron Castings, FC25 Grey Iron Castings, FGG 25 Grey Iron Castings, SjG 25 Grey Iron Castings, FC 25 Grey Iron Castings, SISO 125 Grey Iron Castings, ANSI/ASTM A48 Class 35B Grey Iron Castings, UNS F12401 Grey Iron Casting, ASTM A48/A48M No.35A Grey Iron Casting, EN-JL-1040 Grey Iron Casting, CЧ25, CЧ24-44 Grey Iron Casting, FGL250 Grey Iron Castings, FC25 Class 4 (F12801) with JIS G 5501 Grey Iron Casting, China grade HT250 Grey Iron Castings and customized grey iron casting material grades.

Wind Industrial Supplied Co.,Ltd (WIS) also suppliers the Ductile Iron Castings products, also called the Spheroidal-Graphite Cast Iron products, the material grade include GGG-40 Ductile Iron castings, DIN0.7040 Iron Castings, EN-GJS 400-15 Ductile Iron Castings, EN-JS1030 Ductile Iron Castings, DIN EN 1563-1997, W-Nr. 0.7040 (GGG40) Ductile Iron Castings, GGG 50 and GGG 60 Ductile Iron Castings, ANSI/ASTM A536, 60-40-18 Ductile Iron Castings, UNS F32800, ASME SA 395 Ductile Iron Castings, ANSI/ASTM A536, 65-45-12, UNS F33100 Ductile Iron Castings, ANSI/ASTM A536, 80-55-06, F33800 Ductile Iron Castings, BЧ40 Ductile Iron Castings, BЧ45 Ductile Iron Castings, JIS G 5502 FCD40 Class 1, F32800 Ductile Iron Castings, FCD45 Class 2, F33100 Ductile Iron Castings, NFA 32-201,FGS370-17 Ductile Iron Castings, FGS400-12 Ductile Iron Castings, BS 2789, Cr.370-17 Ductile Iron Castings, Cr.420-12 Ductile Iron Castings, we also manufacture these ductile iron castings and spheroidal-graphite cast iron parts according to the drawing and customized products.

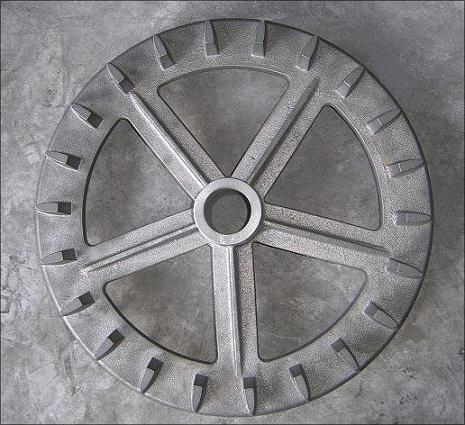

Casting products can vary greatly in size and weight, ranging from a couple ounces to several tons. Some smaller sand cast parts include components as gears, pulleys, crankshafts, connecting rods, and propellers. Larger applications include housings for large equipment and heavy machine bases. Sand casting is also common in producing automobile components, Marine products, Pump and Valve components, engine blocks, engine manifolds, Cylinder heads, and transmission parts.

|

||||||||||||||||||||||||||||||||||||

Every heat produced is analyzed for chemical composition by means of X-ray fluorescence spectrometer. Our equipment is calibrated daily to national standards and custom made secondary standards. Dedicated instruments analyze for lighter elements carbon, sulphur, nitrogen and oxygen. Chemical analysis certificates are provided for every heat ordered.

All incoming material is analyzed by a portable X-ray fluorescence spectrometer, This includes all lots of weld filler metal. Carbon levels are also checked in the chemical lab.